Buying any type of machine is a big deal for most people because it means spending a considerable amount of money. You most likely want to buy something that is going to be a good investment in the long run and meet your needs. Investing in the right machine can make your life easier and even save you money. You should take your time so you make the right choice.

Charcoal is something used by many people across the world. If you have bought charcoal from the store before, you know how expensive it gets. When you look at how much you are spending on charcoal every year, you will be surprised. You don’t have to do that anymore because you can make your own. A rice husk charcoal making machine gives you the ability to make your own charcoal without spending that much. You will make the charcoal from materials like rice husks, coconut shells, sawdust, etc.

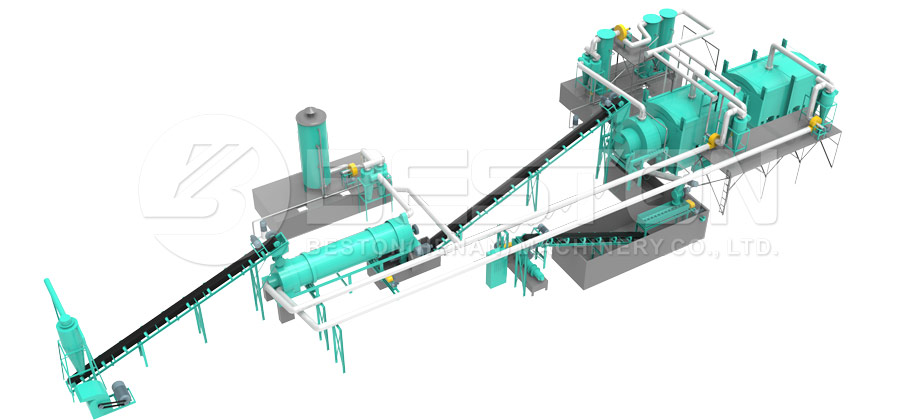

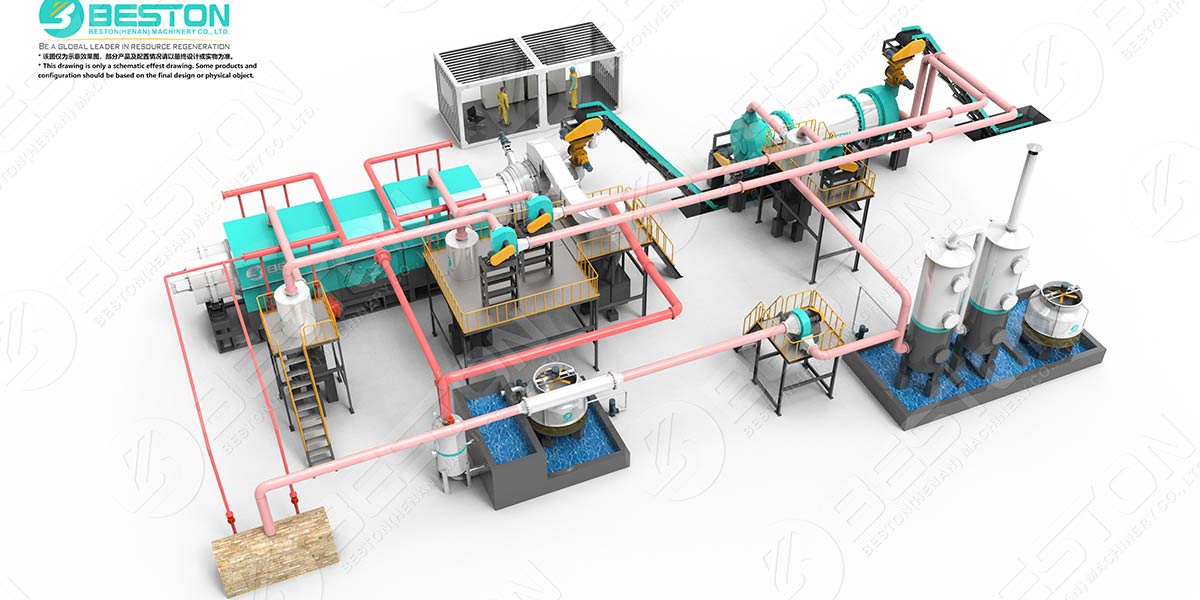

A rice husk charcoal making machine is the best option if you have a lot of rice husks around. These are waste products you can get on the cheap or even free sometimes. By using rice husks to make charcoal, you are doing something good for the environment. Below are some tips to help you when buying a rice husk charcoal making machine.

Your Needs

This is the first thing you need to look at before buying a biomass pyrolysis plant. It will help you narrow down your options and end up with the best fit. What is the amount of charcoal you need the machine to make? Do this then choose a machine that produces what you need. Don’t choose something that produces more than you need because it will cost you more to buy and run. Invest a lot of time and effort into researching the machine.

Size

The size of the risk husk charcoal making machine for sale is going to have a big impact on the price. The bigger ones are usually expensive and it can be challenging to make a good return on investment on such unless it is for commercial purposes. If you have a market for charcoal, then a big one is okay. It is better to get a small one and then add another when the demand grows. This minimizes your risk and you won’t have to experience a lot of losses if things don’t go according to plan.

Budget

A budget is going to put your focus only on those rice husk charcoal making machines you can afford. Imagine putting a lot of time and effort into the process of choosing the right coconut shell charcoal making machine, and then realizing that is way out of your budget. This can make things easier for you because you can just focus on the things you can afford.

A rice husk charcoal making machine is a good investment that will give you a good return. You need to put some effort into choosing something that meets your needs and is within your budget.