In the realm of sustainable energy production, the charcoal making machine emerges as a versatile and efficient tool for converting biomass into valuable charcoal, offering a viable solution for alternative energy generation. This innovative technology harnesses the power of pyrolysis to transform various biomass feedstocks into high-quality charcoal, which can be utilized for cooking, heating, and industrial applications, thereby reducing reliance on traditional fossil fuels and mitigating environmental impact.

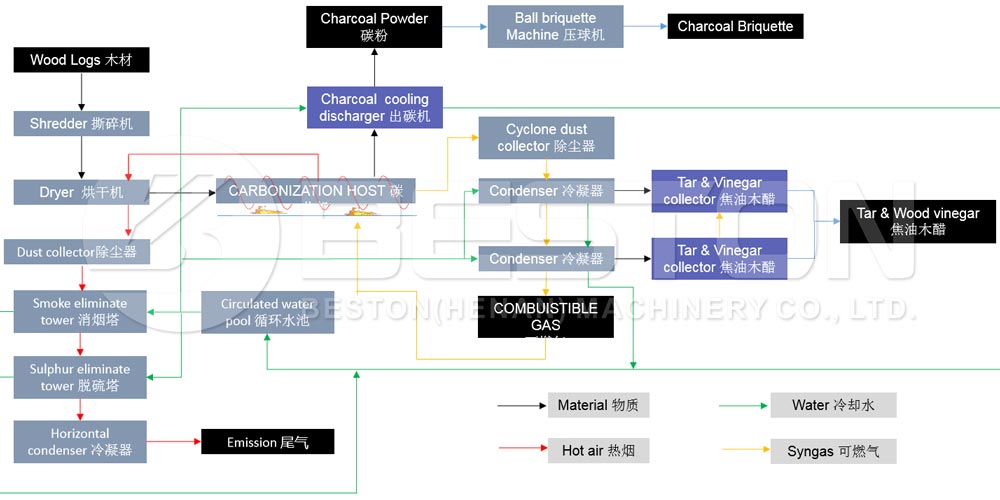

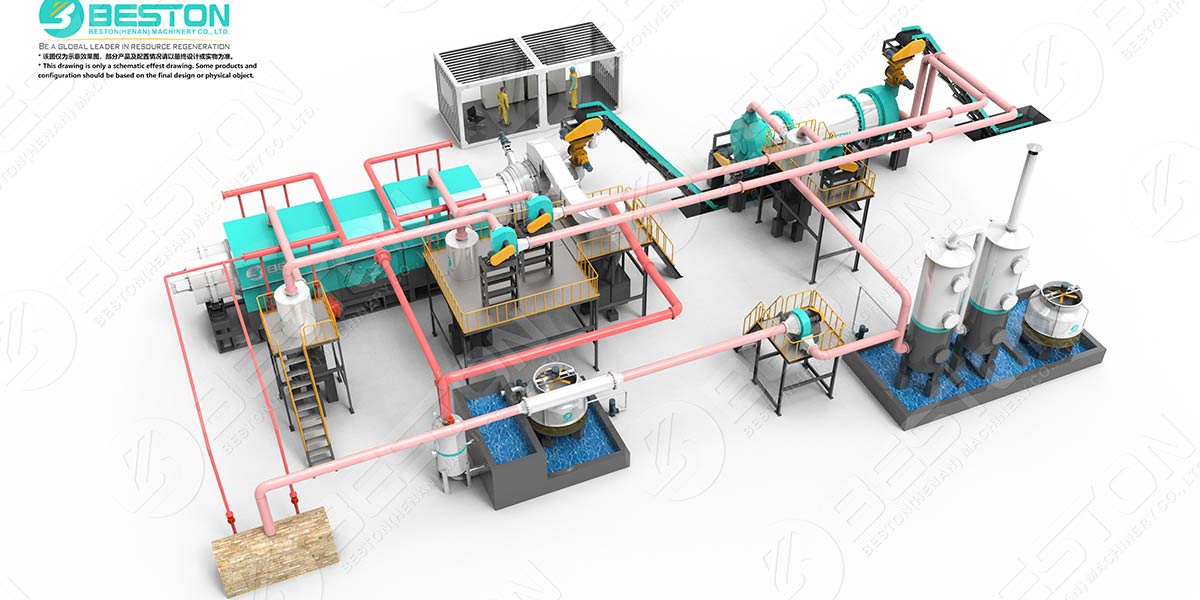

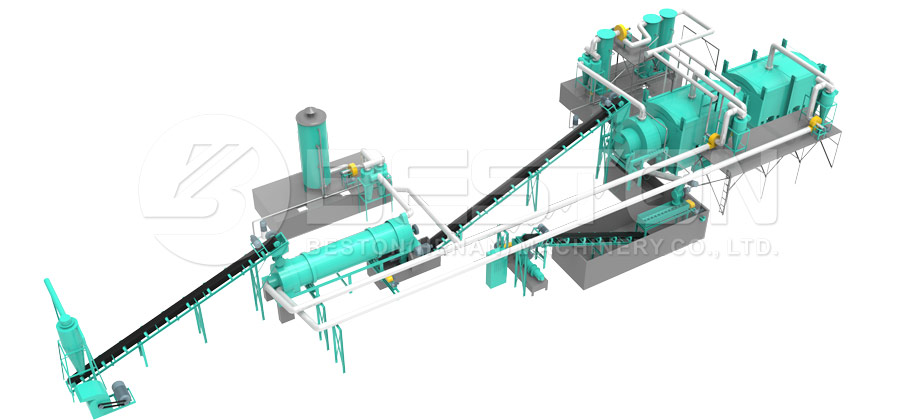

Biomass Conversion Process

At the heart of the charcoal making machine lies the pyrolysis process, wherein biomass feedstock undergoes thermal decomposition in the absence of oxygen, yielding charcoal as the primary product. This controlled heating process breaks down organic materials into carbon-rich char, while also producing combustible gases and bio-oil as byproducts. The resulting charcoal boasts high carbon content and low moisture content, making it an ideal fuel source for sustainable energy production.

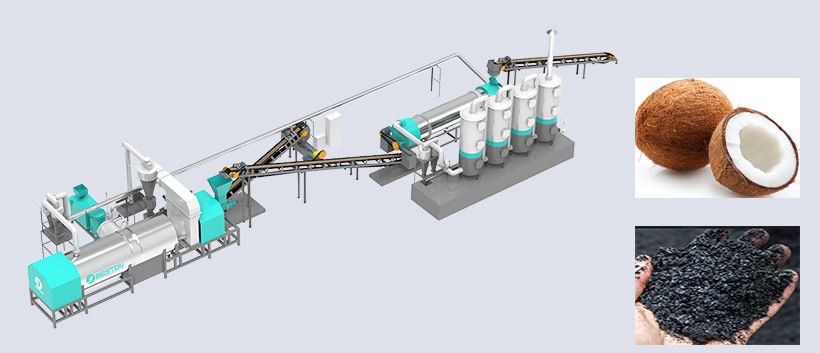

Versatile Feedstock Utilization

The flexibility of the charcoal making machine allows for the utilization of various biomass feedstocks, including wood chips, sawdust, agricultural residues, and even organic waste materials. This versatility in feedstock selection enables resource optimization and waste valorization, as it allows operators to utilize locally available biomass resources and divert organic waste from landfills or incineration facilities, thereby contributing to environmental sustainability and resource conservation.

Environmental Benefits

By converting biomass into charcoal, the biomass pyrolysis machine offers significant environmental benefits compared to traditional energy production methods. Charcoal produced from renewable biomass sources is considered carbon-neutral, as the carbon dioxide emitted during combustion is offset by the carbon sequestered during plant growth. Furthermore, the utilization of biomass-based charcoal reduces reliance on fossil fuels, thereby mitigating greenhouse gas emissions and combatting climate change.

Energy Efficiency

The charcoal making machine is designed for optimal energy efficiency, utilizing advanced pyrolysis technology to maximize charcoal yield while minimizing energy consumption. The efficient conversion of biomass into charcoal results in higher energy density and lower emissions compared to traditional biomass combustion methods. Additionally, the combustible gases and bio-oil generated during the pyrolysis process can be utilized as supplementary fuel sources, further enhancing energy efficiency and reducing waste.

Sustainable Development

As a renewable and carbon-neutral energy source, charcoal produced by the charcoal making machine promotes sustainable development and energy independence. By reducing dependency on finite fossil fuels and supporting local biomass industries, charcoal production contributes to economic growth, job creation, and rural development. Moreover, the utilization of biomass-based charcoal fosters community resilience and environmental stewardship, aligning with principles of sustainable development and green energy transition. For more information please click: https://bestonasia.com/

Industrial Applications

In addition to household cooking and heating, charcoal produced by the charcoal making machine finds diverse applications across various industrial sectors. Charcoal serves as a raw material for metallurgical processes, water purification, activated carbon production, and renewable energy generation. Its high carbon content, porous structure, and chemical stability make charcoal a valuable resource for industrial applications, offering versatility, cost-effectiveness, and environmental sustainability.

Market Opportunities

The growing demand for sustainable energy solutions and alternative fuels presents lucrative market opportunities for biochar machine operators and investors. With increasing awareness of environmental issues and regulatory incentives for renewable energy adoption, the charcoal industry is poised for significant growth. By capitalizing on market demand and technological advancements, stakeholders can unlock the full potential of charcoal production as a sustainable and profitable venture.

Conclusion

In conclusion, the charcoal making machine offers a sustainable solution for alternative energy production, utilizing biomass resources to generate high-quality charcoal for household, industrial, and commercial applications. Through efficient biomass conversion, environmental benefits, energy efficiency, and market opportunities, charcoal production contributes to a more sustainable and resilient energy future. By embracing this innovative technology and leveraging biomass resources, stakeholders can mitigate environmental impact, reduce carbon footprint, and promote economic development while addressing the challenges of energy security and climate change.