Plastic waste has become one of the most pressing environmental issues of our time, with vast amounts polluting our oceans, rivers, and landfills. As the world grapples with the consequences of excessive plastic consumption, innovative solutions are emerging to address the problem at its core. One such solution is plastic to oil conversion, a process that transforms plastic waste into usable fuel. This post explores the technology behind plastic to oil machine, its environmental impact, and the potential it holds as a sustainable fuel alternative.

The Plastic Problem

Plastic production has surged over the past few decades, driven by its versatility, durability, and cost-effectiveness. Unfortunately, these very qualities that make plastic ubiquitous also contribute to its persistence in the environment. According to a report by the World Economic Forum, approximately 8 million tons of plastic enter the ocean each year, causing irreparable damage to marine ecosystems and threatening biodiversity.

Plastic pollution affects not only the environment but also human health. Microplastics, resulting from the breakdown of larger plastic items, find their way into the food chain, posing potential health risks. As the urgency to address the plastic crisis intensifies, innovative solutions are required to mitigate its impact and promote a circular economy.

Plastic to Oil Conversion Technology

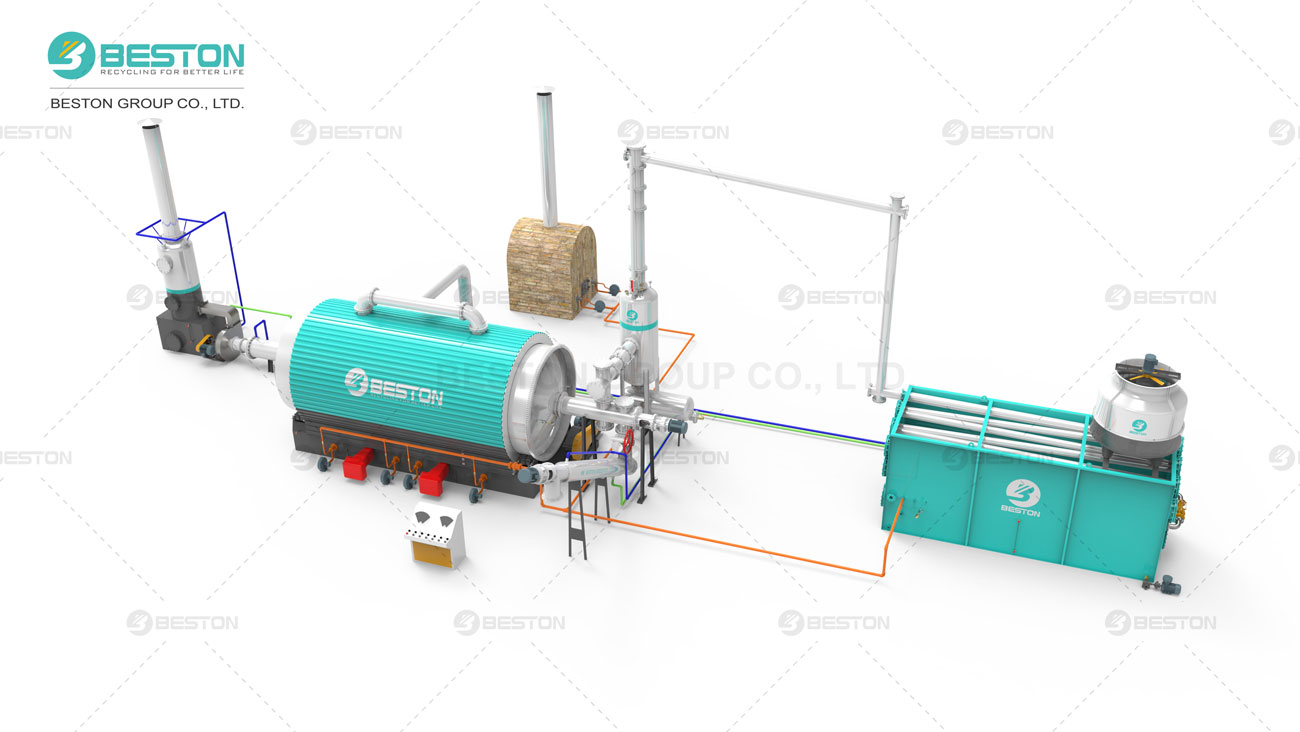

Plastic to oil conversion is a technology that offers a transformative approach to dealing with plastic waste. The process involves breaking down plastic polymers into their constituent hydrocarbons, which can then be refined into fuel. There are different methods employed in plastic to oil conversion, with pyrolysis and depolymerization being the most prominent.

Pyrolysis

Pyrolysis is a thermal decomposition process that involves heating plastic waste in the absence of oxygen. This prevents combustion and instead breaks down the plastic into gases, liquids, and solid residues. The resulting gases can be condensed into a liquid form, commonly referred to as synthetic crude oil or pyrolysis oil.

The key advantage of pyrolysis is its ability to process a wide range of plastic types, including those traditionally considered non-recyclable. This flexibility makes it an attractive option for addressing diverse plastic waste streams. However, challenges such as the need for high temperatures and the management of by-products remain areas of ongoing research and development.

Depolymerization

Depolymerization, on the other hand, is a process that involves chemically breaking down polymers into monomers. These monomers can then be further processed into valuable products, including fuels. While depolymerization can be more selective in its approach compared to pyrolysis, it often requires additional steps to refine the resulting monomers into usable fuel.

Both pyrolysis and depolymerization offer promising avenues for converting plastic waste into fuel, but their scalability, efficiency, and environmental impact are critical factors that need careful consideration in the pursuit of sustainable solutions.

Environmental Impact

While the conversion of plastic to oil presents an innovative approach to waste management, its environmental impact must be thoroughly assessed to ensure that it aligns with broader sustainability goals. Here are key considerations:

Reduction in Landfill Usage

One immediate environmental benefit of plastic to oil conversion is the potential reduction in landfill usage. By diverting plastic waste from landfills, which often contribute to soil and groundwater pollution, this technology helps address the challenges associated with traditional waste disposal methods.

Energy Recovery

The conversion of plastic into synthetic crude oil provides a form of energy recovery from a previously discarded resource. This process can contribute to reducing reliance on fossil fuels and mitigating the environmental impact of conventional energy extraction.

Greenhouse Gas Emissions

While plastic to oil conversion offers potential environmental benefits, it is essential to assess its impact on greenhouse gas emissions. The energy required for the conversion process, as well as the emissions associated with refining the synthetic crude oil, must be weighed against the environmental gains achieved through reduced plastic pollution.

Resource Conservation

By converting plastic waste into a valuable resource like fuel, this technology contributes to resource conservation. It aligns with the principles of a circular economy, where waste is minimized, and materials are continually reused or repurposed.

Challenges and Considerations

Despite its potential, plastic to oil conversion faces several challenges and considerations that warrant careful examination:

Energy Input

The energy input required for the conversion process is a significant consideration. High temperatures and energy-intensive processes, particularly in pyrolysis, can offset the environmental benefits if the energy source comes from non-renewable or carbon-intensive means. Integrating renewable energy sources into the conversion process is crucial for maximizing sustainability.

Economics of Scale

The economic viability of plastic to oil conversion relies on achieving sufficient economies of scale. Smaller-scale operations may struggle to compete with established waste management and energy production methods. Investment, research, and development efforts are needed to optimize the technology for larger-scale implementation.

By-Products and Residues

The by-products and residues generated during plastic to oil conversion must be managed responsibly. Solid residues, often referred to as char or carbon black, can have various applications, such as construction materials or as a component in manufacturing processes. However, careful consideration and regulation are necessary to avoid unintended environmental consequences.

Selectivity and Contaminants

Ensuring the selectivity of the conversion process is critical to producing high-quality synthetic crude oil. Contaminants, such as impurities in the plastic feedstock, can affect the efficiency and quality of the conversion. Innovations in process control and refining techniques are needed to enhance the selectivity of plastic to oil conversion technologies.

Environmental Legislation and Standards

The development and adoption of stringent environmental legislation and standards are essential to guide the responsible implementation of plastic to oil conversion technologies. Ensuring compliance with emissions limits, waste management practices, and product quality standards will help prevent unintended negative consequences.

Case Studies and Success Stories

Several projects and initiatives around the world are actively exploring and implementing plastic to oil conversion technologies. These endeavors provide valuable insights into the feasibility and impact of this innovative approach.

Examining various instances of successful implementations and noteworthy cases sheds light on the tangible applications and positive results achieved through plastic to oil conversion technologies. These real-life examples not only demonstrate the viability of this innovative approach but also underscore its potential benefits in addressing plastic waste and fostering sustainable solutions.

Future Prospects and Innovations

As plastic to oil conversion technologies continue to evolve, several innovations and future prospects are shaping the landscape of this field:

Advanced Catalysis

Advancements in catalysis are crucial for enhancing the efficiency and selectivity of plastic to oil conversion. Researchers are exploring novel catalysts that can improve the yield of high-quality hydrocarbons while minimizing undesirable by-products. Catalytic processes also offer the potential for milder reaction conditions, reducing energy requirements.

Integrated Waste Management Systems

The integration of plastic to oil conversion into comprehensive waste management systems holds promise for maximizing the benefits of this technology. Collaborative efforts that combine plastic recycling, waste sorting, and energy recovery can create holistic solutions for addressing the plastic waste crisis.

Circular Economy Models

Plastic to oil conversion aligns with the principles of a circular economy, where resources are reused, recycled, and repurposed. Future innovations may involve the development of closed-loop systems that minimize waste and optimize the use of resources throughout the entire lifecycle of plastics.

Public Awareness and Education

Raising public awareness about plastic to oil conversion and its potential benefits is crucial for fostering acceptance and support. Educational initiatives can help dispel misconceptions, address concerns, and highlight the role of this technology in mitigating plastic pollution while contributing to a more sustainable energy landscape.

Policy Support and Incentives

Governments and policymakers play a vital role in shaping the future of plastic to oil conversion. Supportive policies, incentives, and regulatory frameworks can encourage investment in research, development, and the deployment of these technologies. Aligning plastic to oil conversion with broader sustainability goals ensures its integration into a comprehensive waste management strategy.

Conclusion

Plastic to oil conversion represents a promising avenue for addressing the environmental challenges posed by plastic waste while providing a sustainable fuel alternative. The technology has the potential to transform plastic, once considered a problematic waste material, into a valuable resource. As innovations continue to emerge and challenges are addressed, plastic to oil conversion may play a pivotal role in shaping a more sustainable and circular approach to plastic waste management and energy production. The collective efforts of governments, industries, and individuals are essential to realizing the full potential of this innovative solution and fostering a future where waste is minimized, resources are conserved, and environmental well-being is prioritized.