In a world grappling with environmental challenges, innovative solutions are imperative. One such solution gaining momentum is the process of tyre pyrolysis, which holds promise for transforming waste management practices. Tyre pyrolysis involves the thermal decomposition of tyres in the absence of oxygen, leading to the production of valuable products like oil, gas, and carbon black. This green technology not only mitigates the burden of tyre disposal but also presents opportunities for resource recovery and sustainable energy generation.

The Problem of Tyre Waste

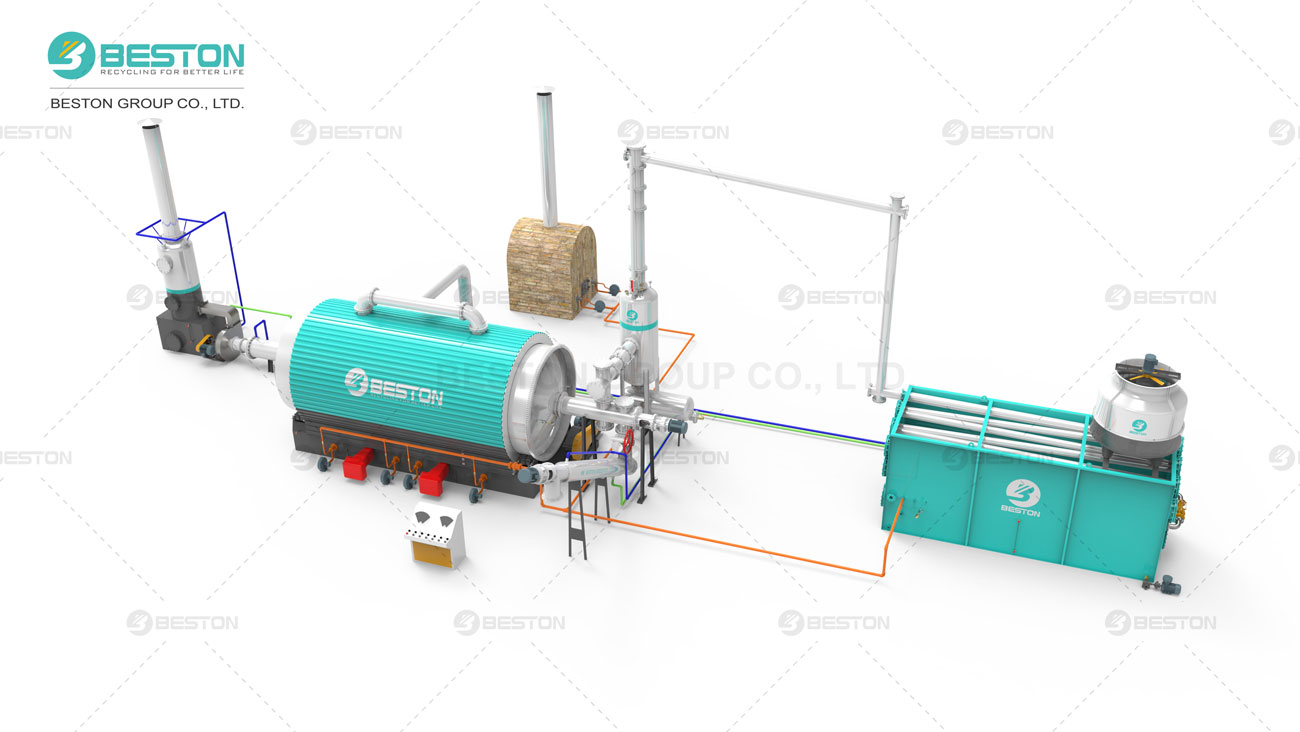

Tyres pose a significant environmental challenge due to their non-biodegradable nature and the sheer volume produced globally. Each year, billions of tyres reach the end of their lifespan, contributing to overflowing landfills, illegal dumping, and environmental pollution. Traditional disposal methods, such as landfilling and incineration, come with their own set of drawbacks, including limited space, air pollution, and health hazards. Waste tyre pyrolysis plant is the high-tech equipment to process tyres.

Understanding Tyre Pyrolysis

Tyre pyrolysis offers a sustainable alternative to conventional disposal methods by converting waste tyres into valuable resources through a thermochemical process. The process typically involves heating shredded tyres in a reactor vessel at high temperatures (around 400-600°C) in the absence of oxygen. This thermal decomposition breaks down the complex hydrocarbons present in tyres into simpler molecules, resulting in the generation of three primary products:

- Pyrolysis Oil: Also known as tire oil or tyre-derived fuel oil (TDF), this dark, viscous liquid contains a mixture of hydrocarbons similar to crude oil. Pyrolysis oil from small pyrolysis plant finds applications as a fuel in industrial boilers, cement kilns, and power plants, offering a renewable alternative to fossil fuels.

- Pyrolysis Gas: Composed mainly of hydrogen, methane, carbon monoxide, and other volatile compounds, pyrolysis gas can be utilized as a source of energy for heating the pyrolysis process itself or further processed into hydrogen or synthetic natural gas.

- Carbon Black: A fine black powder consisting predominantly of carbon, carbon black has various industrial applications, including rubber reinforcement, pigments, and ink production.

Environmental Benefits

The adoption of tyre pyrolysis technology brings several environmental benefits:

- Waste Reduction: By diverting tyres from landfills and illegal dumping sites, tyre pyrolysis helps alleviate the burden on waste management infrastructure while reducing environmental pollution.

- Resource Recovery: Tyre pyrolysis enables the recovery of valuable resources from waste tyres, including oil, gas, and carbon black, thereby promoting resource conservation and circular economy principles.

- Energy Generation: The pyrolysis oil and gas produced out of continuous waste tyre pyrolysis plant can serve as renewable energy sources, displacing fossil fuels and reducing greenhouse gas emissions associated with energy production.

Economic Opportunities

In addition to its environmental advantages, tyre pyrolysis presents compelling economic opportunities:

- Revenue Generation: The sale of pyrolysis oil, gas, and carbon black can generate revenue streams for operators, making tyre pyrolysis financially viable.

- Job Creation: The establishment and operation of tyre pyrolysis plants create employment opportunities across various stages, from collection and processing to marketing and distribution.

- Technology Development: Continued advancements in tyre pyrolysis technology foster innovation and drive research and development initiatives aimed at enhancing process efficiency and product quality.

Challenges and Considerations

While tyre pyrolysis holds immense potential, several challenges and considerations warrant attention:

- Regulatory Compliance: Compliance with environmental regulations and standards is crucial to ensure the safe and sustainable operation of tyre pyrolysis facilities, addressing concerns related to emissions, waste management, and occupational health and safety.

- Technology Optimization: Continuous efforts are needed to optimize pyrolysis processes, enhance product yields, and minimize energy consumption and emissions through technological innovation and process improvements.

- Market Demand: The market demand for pyrolysis products, particularly pyrolysis oil and carbon black, may fluctuate depending on factors such as oil prices, industrial demand, and regulatory incentives, influencing the economic viability of tyre pyrolysis ventures.

Conclusion

Tyre pyrolysis stands as a compelling example of green technology driving innovation in waste management and sustainable resource utilization. By converting discarded tyres into valuable products while mitigating environmental impacts, tyre pyrolysis holds the potential to revolutionize waste management practices, promote circular economy principles, and contribute to the transition towards a more sustainable future. As advancements in technology and regulatory frameworks continue to evolve, tyre pyrolysis is poised to play an increasingly pivotal role in addressing the global challenge of tyre waste while unlocking economic and environmental benefits for society at large. See the thermal desorption unit here.